Nippson Paper Product Information

Nippson PVA transform paper into art. With outstanding adhesion with cellulose due to hydrogen bonding, film strength, barrier properties, binding strength of filler, and dispersing performance, Nippson PVA are used in a variety of paper applications. For example, the specialty grade Nippson PVA enhances and improves paper performance by improving water, chemical, and oil resistance. Nippson PVA offer significant advantages for strength and barrier properties in the commodity and specialty paper market.

Nippson Paper Applications

Adhesion promoter

Carrier of fluorescent whitening agents of Coated Paper

Surface sizing of Coated Paper/Banknote Paper/Paper Board Liner

Inner layer of Silicone Release Liner

Grease-proof paper as fluorochemical extenders

Ink-absorbing layer of ink jet printing paper

Dispersant of leuco dye/developer of thermal paper

Thermal paper top coat agent with a combination of crosslinking agent

Gas barrier paper

Micro-encapsulation aid in NCR paper (carbon-less paper)

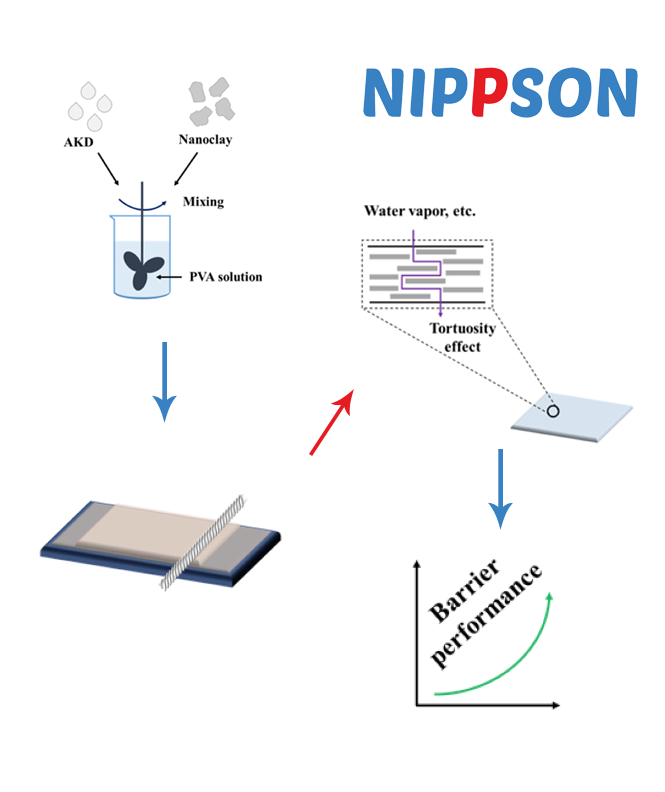

Barrier Performance

Nippson PVA are the strongest waterborne film-formers commercially available to the paper industry. With properties including chemical resistance to oils, waxes, organic solvents, and water, it is the superior material compared to starches and is used as the silicone barrier layer of Release Liner products. Nippson PVA have excellent film formation properties, and films made of Nippson PVA have higher tensile strength than those made from starch alone.Nippson PVA

Packaging für the food industrypaper coating in the industry

Binders and Coatings

Nippson PVA are effective binders in coating formulations at the size press. Because of their excellent binding performance, they can replace starch on a one-to-five basis. With the incorporation of Nippson PVA into binding solutions, the optical and surface properties are improved compared to a clear, uncoated sheet. In other sectors, Nippson PVA are used as powerful binders to produce matte, glossy, or high-speed industrial inkjet papers. Additionally, both are used in thermal dyestuff dispersant, a thermal top coat agent under a combination with a crosslinking agent for thermal paper/label application.Properties:

Improves surface strengthImproves printability

Good compatibility with starches and CMC

Higher water resistance than starch

Lower BOD and COD than starch

Improves binding strength of inorganic substances like filler and silica

Enhances performance of fluorescent whitening agents

Reduces sheet porosity and provides oil and grease barrier

Will absorb water- or glycol-based ink

Will disperse leuco dye/developer of thermal paper

Cross-linking capability

Excellent gas barrier